The Crucial Importance of a Good Vacuum in Your Air Conditioner: Beyond Simple Installation

Discover why properly vacuuming your air conditioning system is essential to ensure its efficiency, durability, and performance. Avoid failures and protect y…

A fundamental step to ensure the efficiency, performance, and long life of your air conditioning equipment.

When installing or repairing an air conditioning system, there is a technical procedure that, although often underestimated by users, is absolutely vital for the proper functioning and durability of the equipment: vacuuming the system. This process is not a mere formality, but a preventative measure that eliminates two of the worst enemies of a cooling system: humidity and non-condensable gases.

What is emptiness and why is it so necessary?

In simple terms, vacuuming an air conditioner involves using a vacuum pump to extract all the air and, more importantly, any moisture contained in the system's pipes before charging the refrigerant gas. Think of it like creating a perfectly clean canvas before painting. Any foreign particles—in this case, water or air molecules—will contaminate the final product.

The air around us, which inevitably enters the pipes during installation, contains water vapor. If this moisture remains inside the circuit, it mixes with the compressor's lubricating oil and the refrigerant itself, leading to a series of catastrophic problems in the medium and long term.

Consequences of Omitting the Void: A Failure Foretold

Failure to create a proper vacuum is one of the main causes of premature failure in air conditioning equipment. The direct consequences of the presence of moisture and non-condensable gases (such as nitrogen and oxygen in the air) are severe:

- Acid Formation and Corrosion:

- Moisture reacts chemically with the refrigerant and oil, creating corrosive acids. These acids attack the system's internal metal components, such as the compressor and piping, generating rust and sludge that clog the circuit.

- Overheating and Increased Energy Consumption: Non-condensable gases do not liquefy in the condenser like refrigerant. Their presence raises the compressor's discharge pressure and temperature, forcing it to work harder than necessary. This directly translates into higher electricity consumption to achieve the same cooling temperature. Poor Cooling Performance: Contamination of the refrigerant with moisture and air reduces its ability to absorb and release heat efficiently. The result is equipment that cools less than expected, even with the thermostat set to minimum. Irreparable Compressor Damage: The compressor is the heart of the system. Corrosion, overheating, and lack of proper lubrication (caused by oil degradation) can lead to catastrophic and costly compressor failure. Expansion Device Freezing: Moisture can freeze at the coldest point in the system, the expansion valve or capillary, creating an ice plug that prevents proper refrigerant circulation.

Benefits of a Career Gap: Investing in Peace of Mind

Creating a deep and correct vacuum, measured with a vacuum gauge until reaching the appropriate levels (generally below 500 microns), guarantees:

- Maximum Energy Efficiency:

- A clean and pure system works effortlessly, consuming the energy for which it was designed and

- reducing your electricity bill

- .

- Optimal Cooling Performance: Your air conditioner will cool quickly and effectively, providing the comfort you expect.

- Long Equipment Life: By protecting the compressor and internal components from corrosion and premature wear, you ensure that your investment lasts for many years.

- Quiet and Stable Operation: A well-bleeded system operates more smoothly and quietly.

Essential Tools for a Professional Vacuum 🛠️

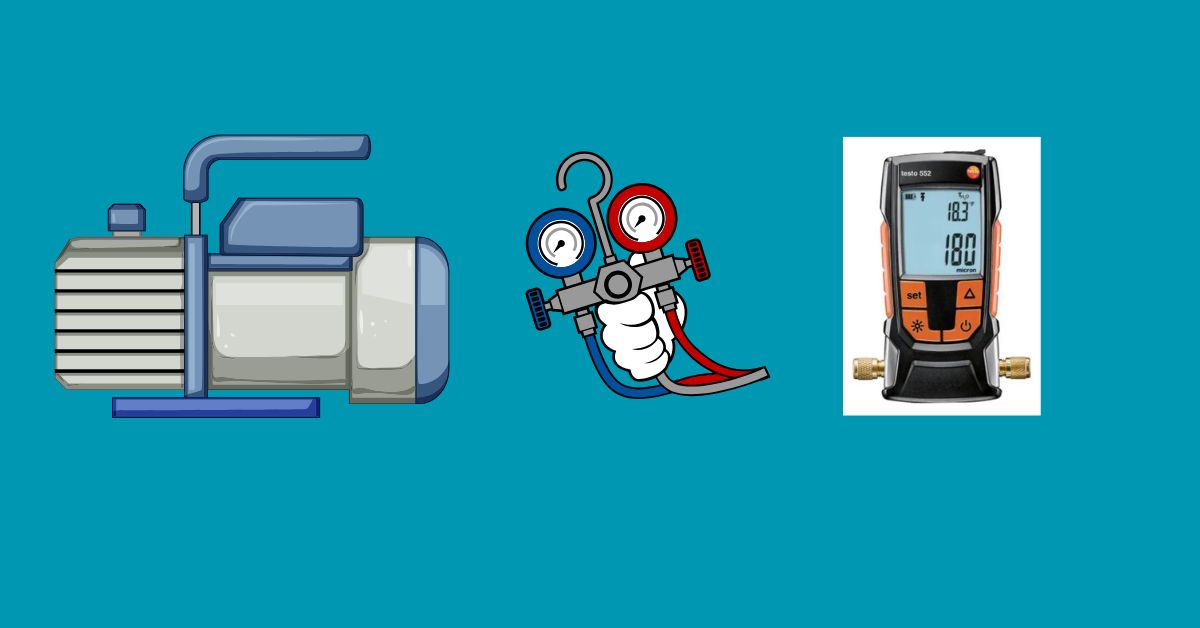

To perform this procedure correctly and ensure the system is completely free of contaminants, a professional technician must use specific equipment. It's not something that can be done "by eye" or with homemade methods. The essential tools are:

- Vacuum Pump:

- This is the process's driving force. This equipment is specifically designed to extract air and moisture from inside the pipes. They come in various capacities (measured in CFM or cubic feet per minute), and the appropriate capacity is chosen based on the size of the system to be evacuated. Its function is to lower the internal pressure to such a low level that the water boils and evaporates at room temperature, allowing it to be extracted as steam.

- Digital Vacuum Gauge: This is the tool that separates a professional from an amateur! It's not enough to simply turn on the pump for "a short while." The vacuum gauge is a high-precision meter that indicates the exact vacuum level reached within the system. It is measured in microns, and the goal is always to reach below 500 microns. Only with this measurement can you be sure that the moisture has been completely eliminated. Relying solely on a traditional pressure gauge is a common mistake that doesn't guarantee a good result.

- Manifold: This is the set of colored hoses and dials that connects the air conditioning unit, the vacuum pump, and the vacuum gauge. It allows the technician to monitor the process, isolate sections, and safely verify system pressures.

A technician who arrives at a facility without these three key tools, especially a digital vacuum gauge, will not be able to guarantee a proper vacuum.

In conclusion, vacuuming is not an option, but an indispensable and critical step in the installation and maintenance of any air conditioning system. Ensuring that the hired technician performs this procedure with the proper tools guarantees the long-term health of your HVAC system. Don't be fooled by "quick and cheap" installations that omit this step; what you save upfront will be more than offset by repairs and higher energy consumption in the future.