Refrigerator Compressor: What It Is, How It Works, and Common Failures

Is your refrigerator not cooling as well as it used to or making strange noises? The problem could be at its heart: the compressor. Discover everything you n…

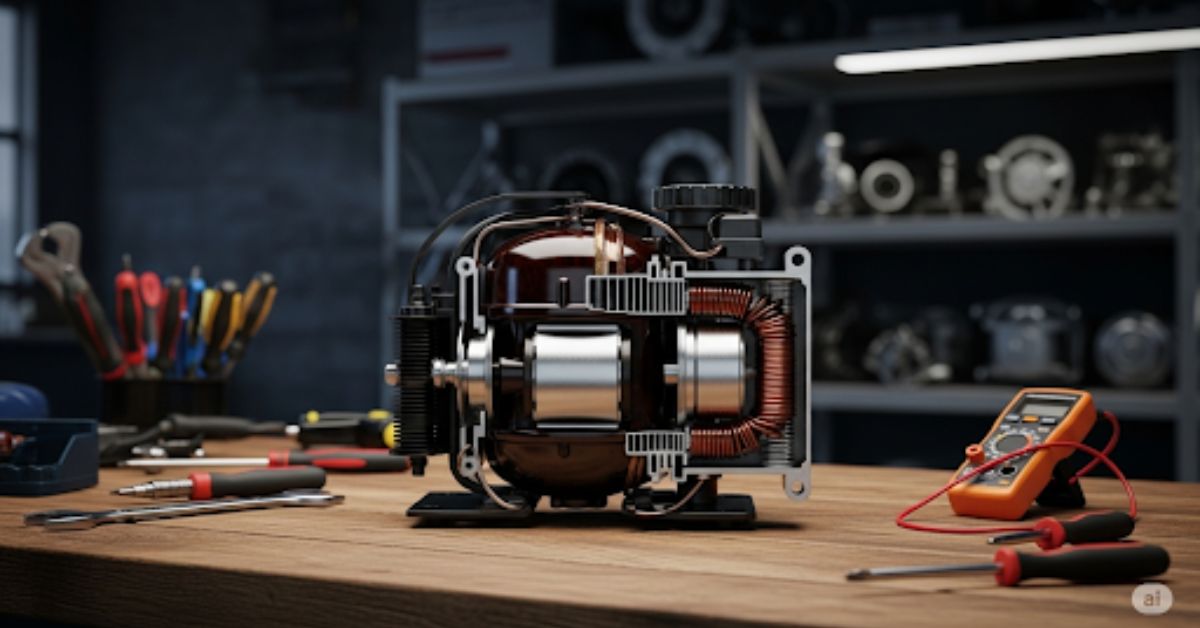

The compressor is, without a doubt, the vital component of any refrigeration system, the true heart of your refrigerator. This motor is responsible for circulating the refrigerant throughout the system, enabling the cooling cycle that preserves your food. Understanding how it works, the types of refrigerant it uses, its most common faults, and how to diagnose a fault can save you time and money.

Types of Compressors and Associated Refrigerants

Not all refrigerator compressors are the same. Technology has evolved to achieve greater efficiency and lower environmental impact. Below are the most common types and the refrigerants they typically use:

- Reciprocating or Piston Compressor: This is the most traditional design and was the standard in home refrigerators for decades. It works similarly to a car engine, with a piston compressing the refrigerant gas.

- Historical Refrigerants: Older models used refrigerants such as R-12 (Freon), a chlorofluorocarbon (CFC) that was banned due to its high impact on the ozone layer.

- Modern Refrigerants: Newer versions of reciprocating compressors may use R-134a, a hydrofluorocarbon (HFC), or R-600a (isobutane), a hydrocarbon (HC) that is more environmentally friendly and energy efficient.

- Scroll Compressor: This type of compressor uses two scrolls, one stationary and one orbiting, to compress the refrigerant. They are known for their quiet operation, high efficiency, and reliability.

- Common Refrigerants: They typically use modern refrigerants such as R-134a and, increasingly, R-600a. In commercial applications, they may also use HFC blends such as R-404A.

- Inverter or Linear Compressor: This is the most modern and efficient technology. Instead of a rotary motor, it uses a piston that moves linearly thanks to an electromagnet. This allows the compressor to adjust its speed according to cooling demand, saving a significant amount of energy.

- Predominant Refrigerants: They almost exclusively use high-efficiency, low-environmental-impact refrigerants such as R-600a (isobutane).

Common Failures: What Usually Goes Wrong?

Despite their robustness, compressors aren't infallible. Certain breakdowns are common, and knowing them can help you identify the problem:

- Overheating: This is one of the most common causes of failure. It can be caused by dirty condenser coils that prevent heat dissipation, a faulty condenser fan, or excessive workload due to improperly closing doors.

- Electrical Problems: Failures in the starter relay, thermal protector, or the compressor motor itself can prevent it from starting. Electrical surges can also permanently damage electrical components.

- Internal Mechanical Failure: Over time and with use, internal parts such as pistons, connecting rods, or scroll coils can wear and break, causing loud noises and causing the compressor to stop. In linear compressors, premature failure of internal valves has been reported in some models.

- Refrigerant Loss or Contamination: A leak in the sealed system will cause the compressor to run dry and overheat. Moisture or air entering the system can contaminate the oil and refrigerant, causing serious internal damage.

- Flooded Start: If liquid refrigerant enters the compressor (designed to compress gas), it can cause "liquid slam" that severely damages valves and pistons.

Practical Guide to Testing a Compressor

If you suspect your refrigerator's compressor is failing, you can perform some basic tests with a multimeter to verify its electrical status. Caution! Before performing any tests, unplug the refrigerator from the power supply to avoid accidents.

- Compressor Access: You'll need to move the refrigerator and remove the lower rear cover to access the compressor. You'll see a round, black casing with several wires connected.

- Component Identification: Locate the starter relay and thermal protector, which are connected to the compressor pins. Disconnect them carefully, taking a photo if necessary to remember their location.

- Coil Continuity Test: The compressor has three pins: common (C), start (S), and run (R). Using the multimeter in ohms (Ω) mode, measure the resistance between the pin pairs: Measure between C and S. Measure between C and R. Measure between S and R. Result: The sum of the first two measurements (CS + CR) should be approximately equal to the third (SR). If the readings are significantly different, or if any measurement indicates "OL" (open circuit), one of the coils is damaged and the compressor must be replaced.

- Ground Short Test: Keep the multimeter in ohms mode. Place one lead on one of the compressor pins and the other lead on a metal part of the compressor (sand the surface lightly to ensure good contact). Result: The multimeter should read "OL" or infinity. If you get a resistance reading, it means the compressor has a ground fault and is dangerous and must be replaced.

- Relay and Thermal Protector Test: Thermal protector: Measure continuity between its two terminals. It should read close to 0 ohms. If it reads "OL," it is defective. Starter relay (PTC type): At room temperature, the resistance between its terminals should be low. If damaged, it may rattle when shaken or read infinite resistance.

These electrical tests are a fundamental first step in diagnosis. If the compressor passes these tests but still doesn't work, the problem could lie with the refrigerator's control board or an internal mechanical failure within the compressor itself. In these cases, the intervention of a qualified technician is the safest and most recommended option.